Current Location: HOME /Knowledge /vertical turbine pump

Current Location: HOME /Knowledge /vertical turbine pump

Date:2024/2/5 22:38:18

Date:2024/2/5 22:38:18 Clicks:

Clicks:

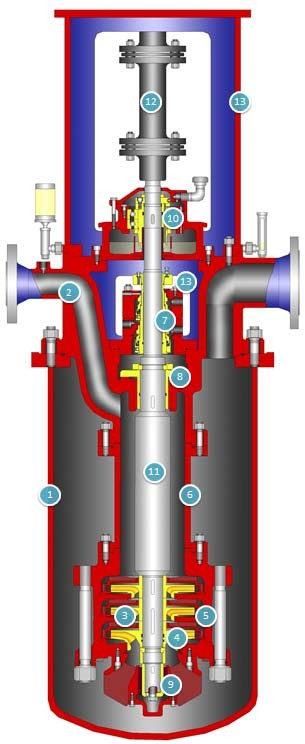

Ø Double-shell construction.

Ø It is rigid enough to withstand the inlet pressure and the pressure difference between the inside and outside of the cylinder.

Ø The installation depth is varied to meet the requirements of the NPSH of the device.

Ø Isobaric design for inlet and outlet.

Ø The inlet and outlet flanges are positioned in various positions to meet the requirements of different pipeline configurations.

Ø The outer casing can be removed and used as a tank or pipeline pump.

Ø The inlet and outlet ends adopt the method of integral casting and inlet and outlet flange welding.

Ø Minimize the axial length of the pump.

Ø Easy maintenance.

Ø There are various types of inlet and outlet flanges to meet the requirements of different sealing types and pressures.

Ø Replaceable pump body and impeller seal rings.

Ø The wear-resistant ring is fixed with interference fit and seam screws.

Ø Precision casting and polishing to ensure the design effect.

Ø The CFD design guarantees maximum hydraulic efficiency.

Ø The first stage impeller has excellent low cavitation performance

Ø Curves without humps.

Ø Closed impellers are standard.

Ø There is a clearance in the axial direction of the impeller. positioning, and the temperature change reduces the deformation of the shaft.

Ø There are two types of runner guide vanes and radial guide vanes.

Ø The guide vane type is selected according to the working conditions.

Ø The radial guide vane has a short axial distance.

Ø The runner type guide vane has a small radial size.

Ø Fully welded, casing connection.

Ø Seamless steel tubing is standard.

Ø A wide range of materials are available.

Ø The cavity meets API610 and API682 standards.

Ø The installation space is large, and various types of mechanical seals can be configured to meet the requirements of various process conditions.

Ø Cartridge mechanical seal is standard construction.

Ø It can be equipped with various types of mechanical seals such as single and double ends.

Ø It can be equipped with dry gas mechanical seals according to the medium situation and the owner's requirements.

Ø Various sealing flushing and cooling schemes can be configured.

Ø Easy to disassemble.

Ø Balance plate device is used to balance the axial force.

Ø Achieve throttling, reduce volume loss, and ensure performance parameters.

Ø Reduce the pressure of the sealing chamber (when conveying saturated or near-saturated media, an external pipe can be used to increase the pressure of the sealing chamber).

Ø It is not easy to lock during operation and is easy to maintain.

Ø Graphite/PTFE bearings are standard, other configurations are also available.

Ø Self-lubricating of the pumped medium.

Ø Bearings are positioned individually.

Ø Mounting according to API610 standard, optimized bearing spacing.

Ø Configured as standard for large inclination mated angular contact ball bearings.

Ø Equipped with machined steel cage.

Ø Thin oil lubrication as standard.

Ø The large oil storage chamber of the bearing box is equipped with an independent internal circulation automatic lubrication system, which can not only effectively lubricate the bearing, but also make the oil temperature constant to ensure the long-life operation of the bearing.

Ø When the temperature of the conveying medium is high, the cooling device can be used to reduce the temperature of the oil chamber.

Ø Large capacity design of oil chamber, large oil storage capacity.

Ø Constant oil cup compensates for lubricating oil online, and oil level gauge detects oil level in real time.

Ø The bearing parts can be disassembled and assembled as a whole, and the maintenance is convenient.

Ø Integral shaft machining, low-stress treatment.

Ø The minimum deflection of the shaft at the mechanical seal is lower than the API 610 standard value, thus increasing the service life of the mechanical seal.

Ø Reasonable coupling method ensures the concentricity of the shaft at the special insertion depth.

Ø Extended diaphragm coupling is standard.

Ø Other types of couplings can also be selected.

Ø The key connection is fixed.

Ø ISO1940-1 G2.5 Balanced Rating.

Ø Complete welding.

Ø The observation hole can also be used as a maintenance hole, and the bearing parts, sealing parts and balance parts can be repaired without disassembling the motor and motor support.

Ø API material options from S-4 to D-2

Ø Meets NACE and low temperature material standards.

Ø The use of corrosion-resistant coatings can improve the service life of critical parts.

Ø Non-metallic wear-resistant parts, which can improve the use environment and improve performance parameters.

Ø Strong corrosive medium, Monel, Hastelloy, duplex stainless steel and other materials can be used.

Ø Other materials can be selected according to the working conditions.

China vertical turbine turbine pump manufacturer provides various stainless steel and duplex steel vertical turbine turbine pumps with affordable prices and stable performance. For more information, please contact 008613974960765.

Scan and add WeChat

TEL:

008618507312158 Xiangyin Industrial Park, Jinlong Town, Xiangyin County, Hunan Province, China

Xiangyin Industrial Park, Jinlong Town, Xiangyin County, Hunan Province, China  susie@hnljpump.com

susie@hnljpump.com Hotline:

008618507312158

008613974960765